Flotation machines - Optimized Mineral Extraction

Flotation machines

The Capiro flotation mechanism inherits the best elements of the renowned Aker flotation technology, while representing an

independent and modern development focused on performance, reliability, and sustainability.

It has been tested against competitors and proven to be the best on the market in terms of recovery, energy consumption, and

lifespan – ensuring an outstanding Return on Investment (ROI). Our flotation machines are designed for demanding industrial

environments, providing stable and reliable separation of valuable minerals.

Optimize your production with Capiro – quality, innovation, and reliability in every step.Optimize your production with Capiro – quality, innovation, and reliability in every step.

Impeller – The Core of the Capiro Flotation Mechanism:

Our impeller represents the latest generation in a long period since 1977, designed to maximize flotation efficiency. Through

extensive optimization of the impeller and air supply system, we have enhanced air dispersion in the slurry. This ensures a

maximum number of microscopic air bubbles, providing an optimal contact surface for mineral particles and thereby increasing

recovery efficiency.

The impeller is manufactured from a specially developed, highly durable material, carefully selected to withstand the demanding

operating conditions of the flotation process. Long-term testing has shown that this impeller is among the best on the market in

terms of overall economy, offering an unbeatable combination of performance, durability, and lower operating costs—

delivering an optimal return on investment.

Stator – Designed for Maximum Turbulence and Efficient Separation:

The stator in the Capiro Flotation Mechanism is designed to interact with the impeller, generating a powerful, turbulent flow in

the lower part of the flotation cell while maintaining a smooth, stable surface layer. This controlled flow pattern enhances

process efficiency by concentrating energy where it's most effective—the lower part of the cell.

The combination of stator and impeller creates intense turbulence, vigorously propelling mineral particles and maximizing

collisions with air bubbles. This high-energy environment significantly increases the probability of valuable minerals attaching to

the bubbles, promoting effective separation from the gangue.

Made from the same durable material as the impeller, the stator features a robust design that ensures long service life and

minimal wear. This reduces maintenance needs and supports consistent, high-efficiency operation over time.

Capiro Flotation Mechanism – Optimized for Maximum Performance

The Capiro Flotation Mechanism is a complete unit designed for efficient mineral recovery through extreme air dispersion andturbulence. The mechanism consists of an impeller, stator, shaft, bearing housing, and system for stator installation from above.Each component is developed with a focus on performance, durability, and operational reliability.

Bearing Housing – The Heart of the Air Supply System

The bearing housing plays a critical role in supplying air to the impeller and incorporates several innovations that enhanceairflow. It is designed to minimize pressure loss and ensure a smooth and efficient air distribution into the system.Key components of the bearing housing include the seals and ball bearings, where we use the best available on the market. Thisguarantees exceptional reliability and longevity, even under demanding operating conditions.

Flexible Stator Mounting Solutions

The stator can be installed in two different ways, depending on the plant’s requirements:

Suspended Mounting

- The stator is attached from above, making it extremely easy to remove the entire mechanism for maintenance without draining the flotation cell.

- This solution simplifies servicing and significantly reduces downtime.

Bottom-Mounted Installation

- The stator is fixed directly to the bottom of the flotation cell, a solution that is easier to install and requires fewer structural modifications.

- The downside is that the cell must be drained to dismantle the stator, which can increase maintenance time.

By offering both mounting options, we provide our customers with the flexibility to choose the solution that best suits their plant and operational conditions.

With this mechanism, we ensure the optimal separation of valuable minerals and an operational economy that delivers a high return on investment.

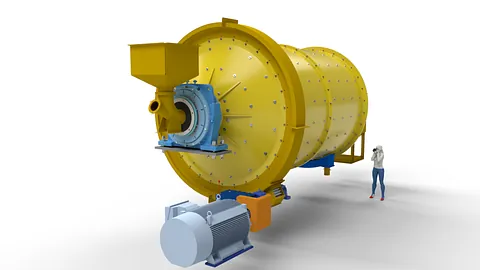

Ball Mills

Ball mills

Capiro offers a range of ball mills tailored for different applications and operating systems, ideal for both small and large processing plants.

Large Ball Mills: Our ball mills, with diameters ranging from 1600mm to 5000mm, can be driven by various systems, including hydraulic drive, electric motors with gearboxes and frequency converters, or permanent magnet electric motors.

Rubber Lining: High-quality rubber linings are offered for all our ball mills, ensuring long service life and reduced maintenance.

Discharge Grate: We provide discharge grates in various sizes and shapes that can be tailored to specific mill requirements.

Spiral – Double-Threaded Systems: For more efficient material handling, we supply both single and double-threaded spiral systems.